Search

Jared Dix wears a lot of hats at Apex Truss, just one of which is Safety Coordinator. One of the things he’s been focused on lately is getting the production employees to be consistent about wearing their personal protective equipment (PPE), specifically their safety glasses.

It’s been a really hot summer and members of the SBCA Safety Committee are always looking for new and different ways to ensure their employees are safe at work, especially when the temperature climbs.

When you first bring a new hire into your plant, there‘s a lot going on that can easily distract someone unfamiliar with component manufacturing. It can be a challenge to keep a new person focused. That said, it’s critical they pay close attention to all of the potential safety hazards, from handling sharp-edged connector plates to learning how to properly swing a hammer.

Prioritizing safety is a continual process and everyone needs to be involved. Its success is dependent on motivating people. I like to think about safety like a good marketing campaign.

Articles

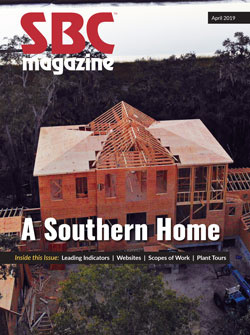

SBC Magazine aims not only to serve as the voice of the structural framing and building envelope industry, it strives to be the main conduit for the information component manufacturers (CMs) find most valuable.

As we start this new year, I want you to consider how much a good idea is worth to you. How much would you pay to purchase a solution that immediately increases your production capacity by five percent or removes a troubling barrier in your market and opens up additional sales opportunities?

Why quarterly insurance policy reviews are important.

A different approach to training new hires.

Why a component manufacturer also became a lawmaker.

It’s not often that a component manufacturer (CM) is asked to do a project that publicly displays the components they design and manufacture. If done right, these opportunities have the potential to positively represent the industry to the entire community.

Using IT to boost production efficiency.

Senior Truss Designer • Nelson Truss • Edgerton, WI

As we enter 2019, we forge our hopes and dreams for the coming year while recalling our fondest memories of the 2018.

Keeping your employees’ hands safe could be as simple as adding a quick toolbox talk at the beginning of your next shift.

Innovation is a word that is currently criticized in the business world for being over utilized. However, I would argue its actual application is being seriously underutilized in our own industry.

Articles

The primary mission of SBC Magazine is to connect with component manufacturers (CMs) from across the country and share their best practices and lessons learned. Of course, the biggest challenge in that effort is identifying the timely struggles of one group of CMs and then finding the CM who has developed a best practice to solve it.

One of the primary missions of SBCA is to help component manufacturers (CMs) gain greater market share. Traditionally, those efforts have been aimed at turning roof rafters into roof trusses, and that focus has paid significant dividends.

You may have noticed the emergence of a new phrase to describe the use of components in certain parts of the country. A method referred to as “offsite framing” is catching on in California, Florida, and other areas of high volume housing production. New techniques always produce mixed emotions of fear, uncertainty, opportunity, excitement, and more.

Past interns are a great fit to attract students. Recently Big C Lumber held a plant tour for 39 students from eight different schools that are in the Michigan Construction Trades course offered through the St. Joseph County Board. After the tour there were at least ten students that showed interest in working at Big C Lumber. That’s a quarter of the students in the tour!

The Baltimore Carpentry Task Force brings students together to explore construction careers

As hiring remote truss designers becomes increasingly common for the component manufacturing industry, ensuring those same designers don’t feel like they’re alone on an island (even if they actually are) needs to be an important factor in your plan. Finding strategies to help all of your employees feel valued and included isn’t a new concept, but shifting the approach for your remote team members can go a long way to establish a solid foundation in your design department.

SBCA is a CM’s best source for understanding the impacts of rulemaking

$270 million project required 9,250 floor trusses, 1,580 roof trusses, and zero call backs

General Manager • Engineered Truss Systems Inc. • Garden City, Kansas

Advantage Truss Company in Hollister, California, had a record year in 2018. They supply exclusively to custom home builders in their market and bid over 1,000 homes last year for the first time in their company’s history (they completed 625 homes). As part of their outreach to the surrounding community, they participate in a local “Lights on Christmas Parade.” Their 2018 entry got a lot of attention.

If you’re looking for ways to improve your in-plant safety program in 2019, many of these are great places to start.

Annandale Millwork & Allied Systems ventured into the components industry differently from most manufacturers as our original business centered on doors and millwork. We diversified into wall panels in the early 1980s and eventually into roof trusses. From the beginning, we’ve always looked to use innovative processes to solve common construction problems.