Quality Decisions Need Quality Data

Quality Decisions Need Quality Data

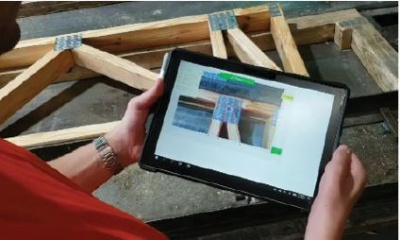

BCMC Session: Revolutionizing the Industry with Digital QC

Josh Dermer, American Truss LLC • Mike Honeycutt, Builders FirstSource • Wyatt Stroder, California TrusFrame LLC • Scott Ward, Southern Components, Inc.

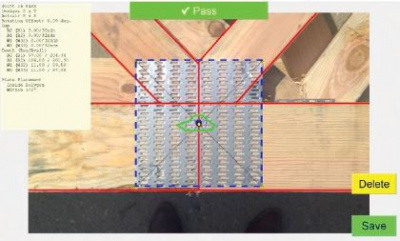

Digital QC is not only about doing QC faster but about getting good data that can be used to make decisions for your business. Being able to do inspections more efficiently is just one of the many benefits that Digital QC can bring. The vision for SBCA Digital QC goes beyond making it easier to meet QC inspection minimums and strives to meet the seven requirements for data to be good: accuracy, legitimacy, reliability, timeliness, completeness, availability, and granularity.

So how can getting good data make a difference in your business? The paramount reason is to minimize your exposure to risk by allowing you to verify the quality of your product before it leaves the plant and potentially at multiple stages along the way. Being able to show photos of trusses and measurements that were taken digitally rather than by hand gives you the ability to respond to any implication that your trusses were manufactured incorrectly.

What is “Good Data”?

- Accuracy

- Legitimacy

- Reliability

- Timeliness

- Completeness

- Availability

- Granularity

The opportunity also exists to take truss measurements throughout the construction cycle of the truss. One example of this is plate embedment measurement being different at the final inspection than during the in-plant inspection. This would show that the truss was manufactured correctly, then handled incorrectly, which would undoubtedly reduce the CM’s liability regarding damage or performance.

Another way good data can help your business is by providing timely information with which to make decisions. Being able to identify one crew that consistently produces more out-of-conformance trusses can help you develop a more effective and targeted training for that crew. In the end, it is less expensive to train someone to build a truss correctly than it is to have to pull plates or make repairs. Having QC information readily available allows a manager to see that measured embedment gap is increasing, which may result in calibrating the rollers to prevent embedment issues from happening.

Component Manufacturing QC Reimagined

The evolution and revolution of Digital QC & 3rd Party Digital QA has begun. sbcindustry.com/sbca-digital-qc