Giving Tours to Students – Technology Is Key

Giving Tours to Students – Technology Is Key

A career in component manufacturing offers a “combination of tech and building something with your hands,” says Steve Szymanski of Drexel Truss Systems in Little Chute, Wisconsin. From his experience inviting students to tour his plant, Steve has learned that using technology in their job is “what’s most important to kids; it’s all technology driven,” he says. “Everything is like a video game, so they relate to that.”

Students from St. Joseph County CTE, watching an automated linear saw cut chords for roof trusses during a tour of Big C Lumber Structural Building Components in Dowagiac, Michigan.

In the first two parts of this article series we discussed why it’s important to welcome students into your component operations, as well as some examples of how component manufacturers (CMs) around the country are developing relationships with teachers and schools in order to do so. This article takes a closer look at what you should be sure to cover once you get them there. When you think about students living in this day and age, it’s not surprising that technology tops the list for many CMs who are interacting with student groups.

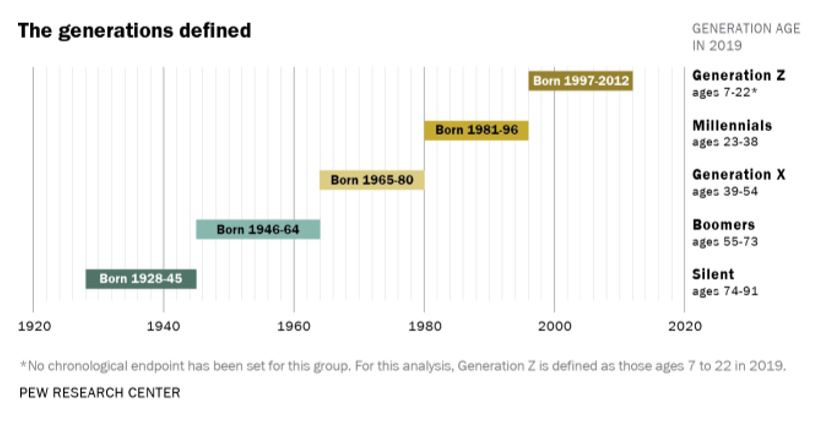

First, a little background on who these students are. Having studied Millennials for more than a decade, the Pew Research Center decided in 2018 to use 1996 as the last birth year for Millennials in their ongoing work, therefore, “anyone born between 1981 and 1996 (ages 23 to 38 in 2019) is considered a Millennial, and anyone born from 1997 onward is part of a new generation.” The most common name for this new group is Generation Z but they are also sometimes referred to as the iGeneration due to

them having no memory of a time before smartphones and social media.

With more than 23 million Gen Z in the U.S., they are soon to become “the fastest-growing generation in both the workplace and the marketplace,” according to the Center for Generational Kinetics (CGK). With so much written and discussed over the past several years about the stereotypical Millennial being lazy and entitled, it is noteworthy that CGK reports “Gen Z is growing up to look more like their practical Gen X parents than their wide-eyed Millennial predecessors; their experiences so far have taught them that life isn't going to be fair, it will be what they make it.”

That being said, there will be challenges with Gen Z, which are primarily technology driven as well. Recent research shows that the use of technology for today’s teenagers is all about their smartphones. Pew’s 2018 survey on teen technology use included two notable findings:

- 95 percent of teens report they have a smartphone or access to one (up 22 percent from their 2015 overview).

- 45 percent of teens say they are online “almost constantly” (nearly twice what was reported in the last survey).

Which brings us back to technology in the truss plant. Steve says he makes a point to highlight the technology that they’re using. “There’s more to it than people think,” he says. “The tour gives them a taste that it’s high tech and they are surprised by the amount of computer use in the plant.” Steve points out the touch-screen monitors at every station in the plant and that “even in the most manual type of job there is still technology usage.”

Like Steve, Rick Moto at Toll Integrated Systems, Inc. has also discovered that hands-on jobs with a technology component are appealing to the students who come through the plant. “They gravitate to the screen,” observes Rick, manufacturing systems manager in Morrisville, Pennsylvania. “They aren’t looking for a paper plan.” He shows them what used to be a manual job and they see a computer screen. “They like that,” says Rick. “The majority of students that come through have that ‘gee whiz’ look in their eyes because they never knew this was how a home is built.”

Andy Green, design manager at Cascade Mfg Co in Cascade, Iowa, also agrees that the technology side of the business needs to be a “big piece” of what students see when they come in for a tour. “Whether it’s showing how a layout comes together or the technology in the manufacturing facility, it’s an eye opener for the students – how we get from point A to point B,” says Andy. “They have no idea before they come for the tour.” He says the tech in the plant usually catches students off guard. “When they see how the saw takes the info from the office and does six cuts – that gets their attention,” he says. “They like knowing they’ll work with computers – even in the shop.”

“It seems likes students today are more inquisitive than they were 25 years ago,” remarks Bob Mochinski, vice president of operations at Littfin Lumber Co. in Winsted, Minnesota. “We’re dealing with a generation that has such a firm grasp of technology – they see things happen and they understand what’s going on. That seems to draw them out.”

The final installment of this series will dive into how CMs prepare for student tours and tailor their tours for different ages and interests. Do you have a perspective to share on reaching Gen Z with career opportunities in the components industry? We’d love to hear from you at editor@sbcmag.info.