A Designer’s Guide to PTW

A Designer’s Guide to PTW

Metal plate connected wood trusses are sometimes used in applications or environments that require the trusses to be designed and constructed with chemically treated lumber. The two most common types of chemically treated wood used in trusses are preservative treated wood (PTW) and fire retardant treated wood (FRTW).

Chemicals and treatment processes can require reductions in the strength and stiffness design properties of the wood or the lateral resistance strength (i.e., grip) of the connector plates. They can also require additional corrosion protection for the connector plates.

The building designer is responsible for specifying any type of wood treatment to be used. Section 2.3.2.4(g)(6)(iii) of ANSI/TPI 1-2014 requires construction documents include information concerning moisture, corrosive chemicals and gases expected to result in corrosion potential from wood treatments or other sources that can be detrimental to trusses.

Still, truss design technicians need a basic understanding of the potential effects the various treatments can have on the lumber and connector plate properties so appropriate adjustments can be made during the design process to ensure the trusses perform as intended by the building designer.

Preservative treated wood (PTW) is typically specified for wet service applications where the moisture content of the wood is expected to exceed 19 percent for an extended period of time or where the wood is susceptible to attack from wood destroying insects such as termites. Sustained high moisture conditions are ideal environments for decay-causing fungi, which destroy wood fibers, thereby greatly reducing the strength of the wood. Preservative treatment chemicals inhibit fungi growth, and they make wood distasteful to insects.

Preservative treated wood (PTW) is typically specified for wet service applications where the moisture content of the wood is expected to exceed 19 percent for an extended period of time or where the wood is susceptible to attack from wood destroying insects such as termites. Sustained high moisture conditions are ideal environments for decay-causing fungi, which destroy wood fibers, thereby greatly reducing the strength of the wood. Preservative treatment chemicals inhibit fungi growth, and they make wood distasteful to insects.

There are three key things a truss design technician needs to keep in mind when designing for conditions that call for PTW:

1. Design Value

The preservative treatments currently approved for use in the United States do not require a reduction in lumber design properties due to the chemicals used in the treatment process. As a result, the design values published in the National Design Specification® for Wood Construction (NDS®) and the NDS Supplement, apply to both preservative treated and untreated lumber used in trusses. The design value adjustment factors in the NDS also apply to both treated and untreated lumber, with the exception that the maximum load duration factor for PTW products used as structural members is limited to 1.6.

2. Incising

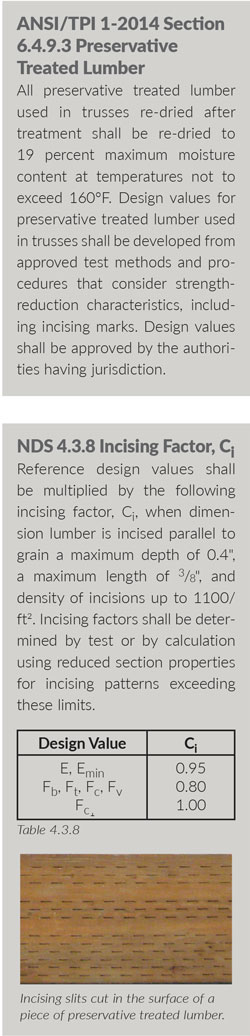

Some species of wood must be incised to obtain deep and uniform penetration of the preservatives, thus improving the effectiveness of the treatment. Incising means making shallow slits parallel to the grain of the wood, which reduces both the strength and stiffness of the lumber.

3. Corrosion

Some chemicals used in PTW can have a corrosive effect on the connector plates. Borate-based preservatives are no more corrosive than untreated lumber, so typical G60 galvanized metal connector plates can be used with lumber treated with these preservatives. However, borate-based preservatives are intended only for applications where the lumber is continuously protected from liquid water, such as interior areas. Copper-based preservatives, such as Alkaline Copper Quat (ACQ) and Copper Azole (CA-B, CA-C, MCA-B and MCA-C), require connector plates that are G185 galvanized, post-manufactured hot dip galvanized per ASTM A153, or stainless steel.

In summary, trusses intended for a dry-service application (i.e., where the moisture content of the wood is not expected to exceed 19 percent) using PTW that is not incised and that has been either Kiln-Dried After Treatment (KDAT) or Air-Dried After Treatment (ADAT) to a maximum moisture content of 19 percent (per Section 6.4.9.3 of ANSI/TPI 1) can be designed using the same design value adjustment factors as trusses using untreated lumber.

If the PTW is incised, the lumber and plate grip design values must be adjusted using the appropriate incising factor, Ci. If the intended application is one where the moisture content of the wood is expected to be greater than 19 percent for an extended period of time, the design values for the lumber and plate grip must be adjusted using the wet service factor, CM.

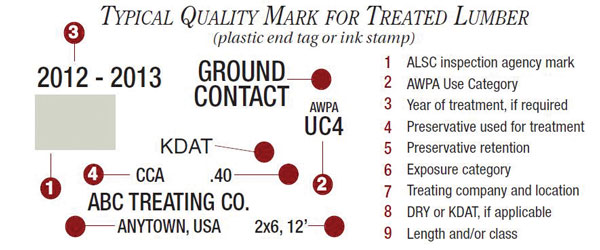

Finally, truss manufacturers should use only preservative treated wood bearing ink-stamped quality marks or plastic end tags indicating the material was produced under supervision of an independent inspection agency accredited by the American Lumber Standards Committee (ALSC). Quality marks confirm the preservative treated wood conforms to the minimum requirements of the building code.

To avoid potential issues, always check with the preservative treatment supplier, the connector plate supplier and the truss design engineer to determine the appropriate adjustments for the wood and plate strength values and the type of corrosion protection to use.

IBC 2015 2303.1.9.1 Identification.

Wood required by Section 2304.12 to be preservative treated shall bear the quality mark of an inspection agency that maintains continuing supervision, testing and inspection over the quality of the preservative-treated wood. Inspection agencies for preservative-treated wood shall be listed by an accreditation body that complies with the requirements of the American Lumber Standards Treated Wood Program, or equivalent. The quality mark shall be on a stamp or label affixed to the preservative-treated wood, and shall include the following information:

- Identification of treating manufacturer.

- Type of preservative used.

- Minimum preservative retention (pcf).

- End use for which the product is treated.

- AWPA standard to which the product was treated.

- Identity of the accredited inspection agency.

Image courtesy of the Southern Forest Products Association

Checklist for Designing with PTW:

- Contact the truss design engineer and metal connector plate supplier to discuss the truss application and treatment being specified before bidding the job. The engineer or supplier can determine the design criteria and connector plate type to use. All steel components (fasteners, hangers, etc.) that come in contact with the treated wood will need the same corrosion protection. Avoid exterior exposure of metal plate connected wood trusses because such applications often result in repetitive wetting and drying of the wood members, which can cause the plates to “back-out” due to the swelling and shrinking of the wood.

- Consult the customer and the building designer for review and approval of any proposed wood treatment substitution.

- Apply the appropriate adjustments to the design values of the lumber and plates to account for the type of treatment and the environmental conditions. Typically, this means selecting the appropriate treated lumber from the materials inventory in your design software, which already includes the strength reductions. It can also mean designing with untreated lumber and adjusting the lumber and plate grip load duration factors. The truss design engineer can determine the best procedure to follow.

- Provide the material safety data sheets (MSDS) for the treated lumber with the truss shipment.